|

|

|

|

|

Seam Tracking Sensor |

|

|

|

|

|

KT-300

is an easy to use weld tracking system,

can detect arc light and welding gun at

the same time, real-time tracking, and

be used in all kinds of existing

automation systems without weld tracking

function. The system is equipped with a

built-in 2D photoelectric vision module

for welding process monitoring. With

strong industrial design, the system is

suitable for a variety of harsh

application environments. |

|

|

|

|

◆System

performance |

◆External

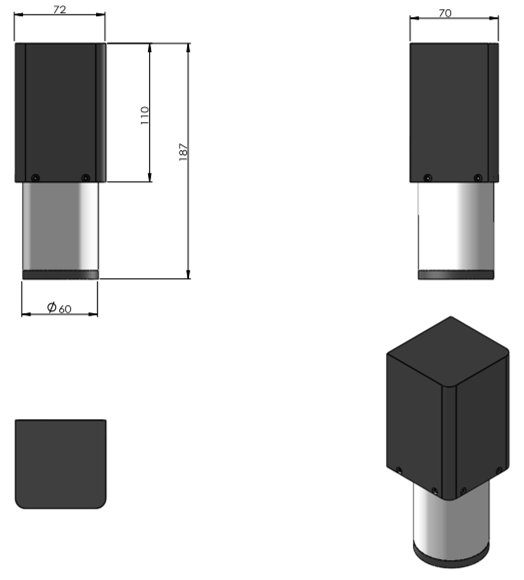

dimension |

■ No manual

participation is required to achieve

automatic

tracking alignment.

■ Non-arc interference (splash, heat,

smoke, magnetic, field,

shock, vibration).

■ Not affected by ambient lighting

conditions.

■ High speed digital photoelectric

sensor to realize fast and

reliable weld recognition.

■ The high speed servo motor linear

module is used for the

accurate and fast positioning of the welding gun.

■ Suitable for piping and plate seam

welding.

■ 405nm blue laser.

|

|

|

|

|

|

◆Performance

parameters

|

|

Welding

gun tracking accuracy |

±0.02mm |

|

Photoelectric tracking resolution |

20μm |

|

Welding

gun horizontal adjustment |

0.05 mm—100 mm |

|

Welding

gun displacement range |

2mm—15mm |

|

Welding

gun adjustment period |

50Hz |

|

Tracking

parameters |

Intelligent self-adjustment |

|

Sensor

to workpiece distance |

200 -

300mm |

|

Sensor

field range |

50mm |

|

Voltage |

220V AC |

|

Current |

2A(maximum) |

|

Alarm

output |

10A

relays |

|

Linear

module manual adjustment interface |

Run +

direction |

|

Protection grade |

IP64

(equipped with googles) |

|

Service

temperature |

5ºC

- 40ºC |

|

Storage

temperature |

-10ºC -

80ºC |

|

Humidity |

Maximum

90% , no frost |

|

|

|

|

◆Applications |

|

|

|

|

|

|

|

Straight

seam welding of carbon steel

pipe,straight seam

welding of stainless steel pipe,

straight seam welding of flat plate |

Straight seam welding

of carbon steel pipe,straight seam

welding of stainless steel pipe,

straight seam welding of flat plate |

|

|

|

|

|