|

|

|

|

HLS-1000 halogen tungsten light source is a

versatile light source, suitable for VIS-NIR

(340 nm-2000 nm), can be used for sample

detection in absorbance transmittance. The light

source can adjust SMA905 connector. The cooling fan cools and stabilizes the

light source. Filter can be embedded in groove

at light exit port. |

|

|

|

|

|

|

■

Specifications: |

|

|

|

Model |

HLS-1000 |

|

Spectrum Range |

340 nm - 2000 nm |

|

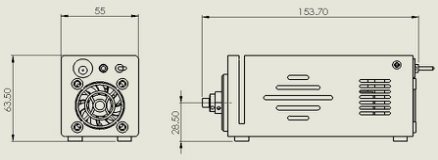

Dimensions (mm) |

153.70×63.5×55 |

|

Weight |

0.63 kg |

|

Energy Consumption |

~8 W |

|

Power Supply Requirements |

12 V DC 4A stabilized

voltage supply |

|

Color Temperature |

2800K |

|

Lifetime of Bulb |

~2,000 hour |

|

Rated Power of Bulb |

5 W |

|

Connector |

SMA 905 |

|

Output Power |

6.0 mW |

|

Warm up Time |

10 minutes |

|

Working Temperature |

5-35°C |

|

|

|

|

Note: The output power is typical value when

connected to a 600 μm core UV / VIS fiber. |

|

|

|

|

|

|

|

|

■

Instructions: |

|

|

|

1.

Connect 12V DC 4A stabilized voltage supply,

power the equipment; |

|

2. Turn the rocker switch to ON to start up; |

|

3. The optical exit port can be connected to

optical fiber, or directly to the optical

receiver; |

|

4. When using the halogen tungsten light source,

it needs to warm up 10 minutes to ensure the

stability of the wavelength. |

|

|

|

|

|

Dimensions of light source |

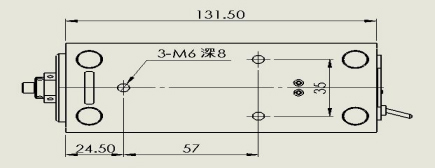

Installation hole map at the bottom

of the light source |

|

|

|

|

|

|

|

|

■

Related Applications and

Solutions: |

|

|

|

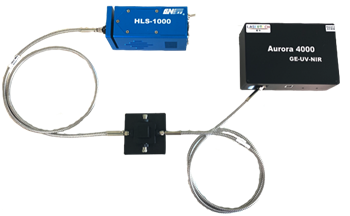

1.

Transmittance

Measuring Experiment |

|

|

|

In this

experiment, the HLS-1000

halogen-tungsten light source is

connected to a three-channel sample

cell and a cuvette by optical fiber.

The light beam passes through the

cuvette and another fiber is

connected to Aurora 4000

high-resolution spectrometer which

is produced by our company. The

transmittance of the liquid is

obtained by software operation. |

|

|

|

|

|

|

|

|

|

|

2.

Reflectivity Measuring Experiment |

|

|

|

In this

experiment, a specially designed

Y-type fiber is connected to the

HLS-1000 halogen tungsten light

source, and the receiver is

connected with the Aurora 4000

high-resolution spectrometer which

is produced by CNI. The probe part

of the optical fiber is fixed on the

optical fiber support, facing to the

test samples. The reflectivity of

the object can be obtained by

software operation. |

|

|

|

|

|

|

|

|

|

|